Welcome to the official website of LIKE!

What is a guiding control system?

Author:

Release time:

2023-03-02

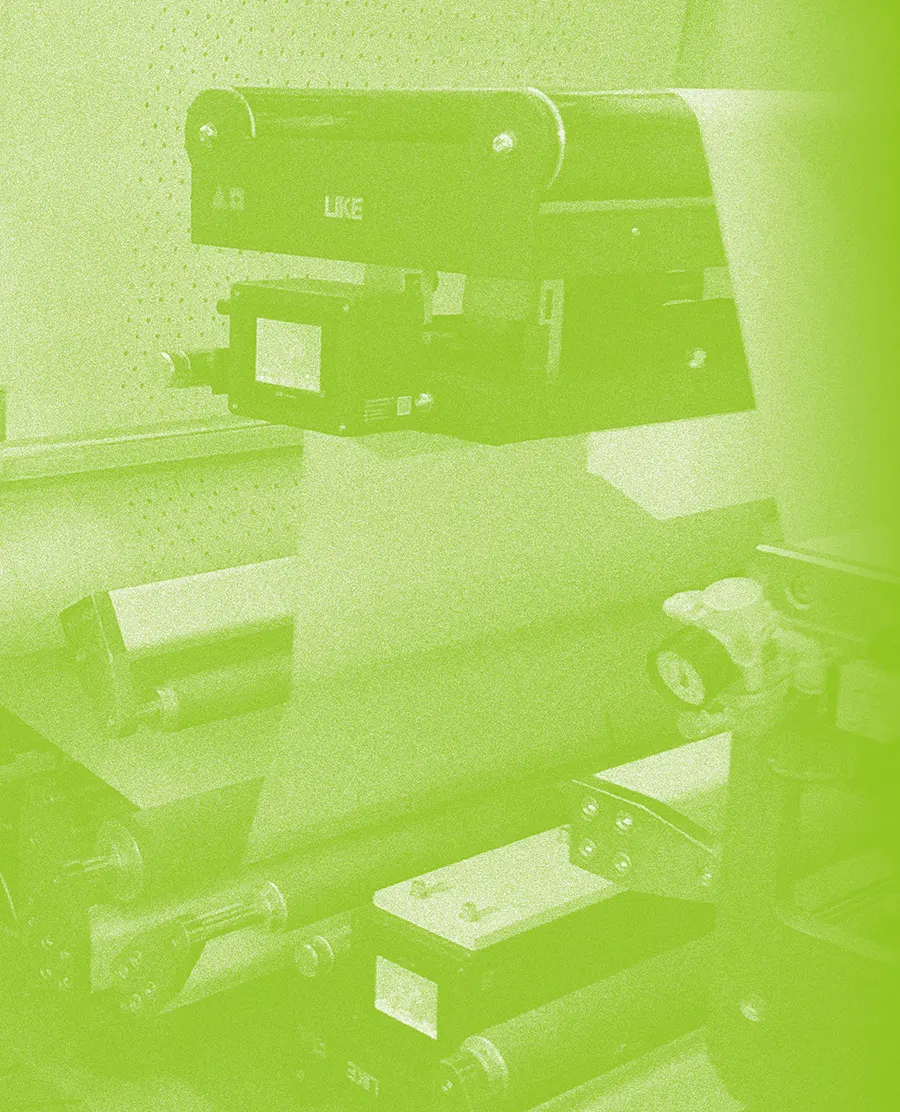

Guiding control systems refer to the technical operations used by manufacturers to keep the sides of the coil neat and consistent during spraying, printing, stamping, lamination, slitting or other coil winding processes. It is widely used. Bring great benefits to the industry. The guiding control system has spawned DE automatic control in steel, corrugated paper, textile, printing, labeling, papermaking, plastic film, building materials, cable, rubber, tire, non-woven corrugated processing and other industries.

The principle of the guiding control system: the guiding sensor emits infrared light/ultrasonic/laser/visible light to monitor the operation of the coil and send the signal to the control device. After the control device finds the coil drift position, the driver controls the correction frame to swing according to the preset command of the control device to correct the coil position. The guiding control system uses a photoelectric sensor to detect the edge position of the coil and send the measured position error signal to the control device. After the control unit judges the treatment, the control drive motor corrects the deviation of the coil to the correct position.

Guiding control systems can provide several different detection methods: edge detection, tracking, or alignment. The drive system adopts low-speed synchronization, frequency conversion speed regulation, stepper and servo motor drive, and the drive stroke has a strict proportional relationship with the coil bias. The guiding control system can also be equipped with different probes to meet the needs of detecting different coils, such as infrared photoelectric, analog infrared photoelectric, etc. Microcomputer digital control equipment provides accurate control of the functions of the guiding control system.

Guiding control system maintenance requirements:

(1) Clean and tidy: tools, workpieces, accessories are neatly placed; Complete safety protection devices; Complete pipelines and piping.

(2) Cleaning: internal and external cleaning; All sliding surfaces, screws, gears, racks, etc. are free of oil and scratches; All parts contain no oil, water, air or electricity; Cut waste clean.

(3) Lubrication: add oil and change oil on time, and the oil quality meets the requirements; The fuel tank, oil gun, oil cup, linoleum, oil circuit are clean, the oil label is bright, and the oil circuit is smooth.

(4) Safety: the implementation of fixed personnel and fixed machines, fixed shift system; Familiar with the maintenance structure of the guiding control system, abide by the operating procedures, reasonably use the correction control system, carefully maintain the tools, and prevent accidents.

RELATED NEWS

2023-04-06

Routine maintenance of correction

2023-04-06