Welcome to the official website of LIKE!

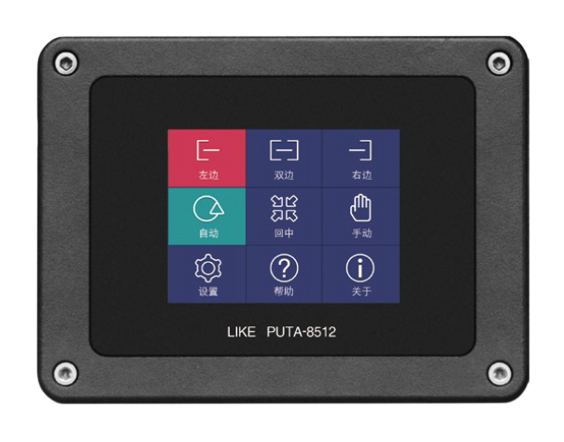

Method of operating the photoelectric correction system

Author:

Release time:

2023-04-06

Due to the good photoelectric switch, the detection distance meets the requirements. According to the packaging paper you use, refer to the following light source selection guide table to determine the switching light source (take green as an example) and then decide the bright or dark motion of the output mode according to the mechanical needs of your photoelectric entanglement system. Finally, adjust the sensitivity according to the following three steps (the following according to the output lighting mode, the packaging symbol is light color, and the back shadow is dark as an example).

(1) Move the wrapping paper so that the light projection point falls in the back area after the mark, rotate the sensitivity in reverse to the end, and then slowly rotate clockwise until the indicator light is just on. Remember the potentiometer position (point A) at this time.

(2) Then move the wrapping paper so that the projection point falls in the center of the mark, at this time the indicator light is on, and then slowly rotate the adjustment torque in the counterclockwise direction until the indicator light is just off, remember the twist position at this time (point B).

(3) After completing the above two steps correctly, the potentiometer can be twisted in the middle C position of A and B, and the adjustment is completed. The larger the distance between A and B, the larger the color difference and the more stable the detection. However, there should be at least one block away from the two points A and B, otherwise the detection will be unstable.

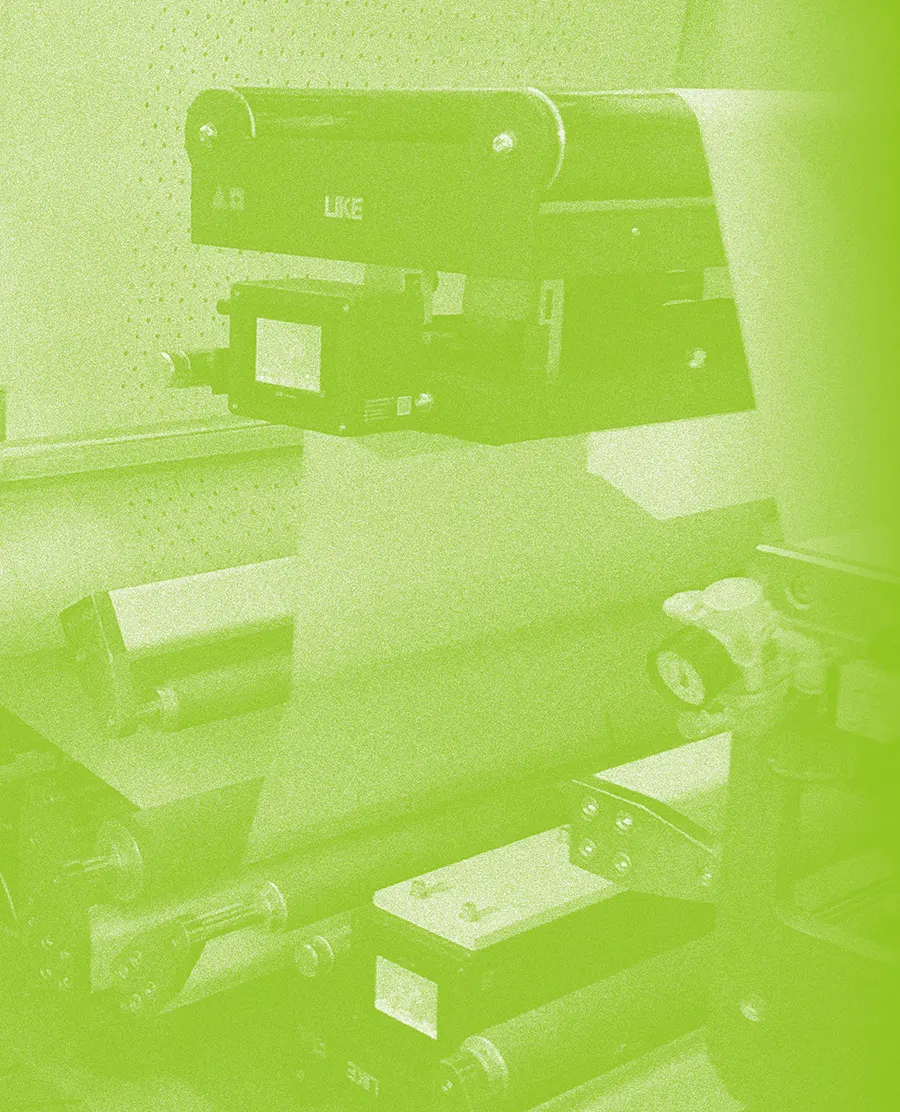

The high-precision MYJP series paperboard guiding curtain is suitable for high-precision inspection and measurement. Including precision correction, online correction, online pair and other similar detection and measurement. The improvement of the control accuracy of the cardboard to the medium light curtain greatly reduces the trimming allowance of the paperboard and improves the input-output rate of the paper material.

Cardboard alignment light curtain (cardboard correction light curtain) principle:

Including at least two sets of detection mechanisms installed respectively to detect the horizontal position and offset of the paper material, programmable controller, guiding motor on the base paper holder, the detection mechanism is placed between the base paper holder and the forming machine, the detection mechanism is under the control of the programmable controller, the horizontal position and offset of the paper material is detected, the detected horizontal position and offset data are transmitted to the programmable controller, the programmable controller compares the detected horizontal position and offset, After the calculation, output the control correction instruction to the guiding motor, move the horizontal position of the paper material, and align the paper material vertically.

The detection methods of MYJP series paperboard guiding light curtain mainly include:

1. Single set of single-side detection-correction light curtain

2. Two sets of single-sided detection-correction light curtains

3. Single set of bilateral inspection - centering light curtain

RELATED NEWS

2023-04-06

Routine maintenance of correction

2023-04-06