WEB GUIDING

CONTROL PROCEDURES

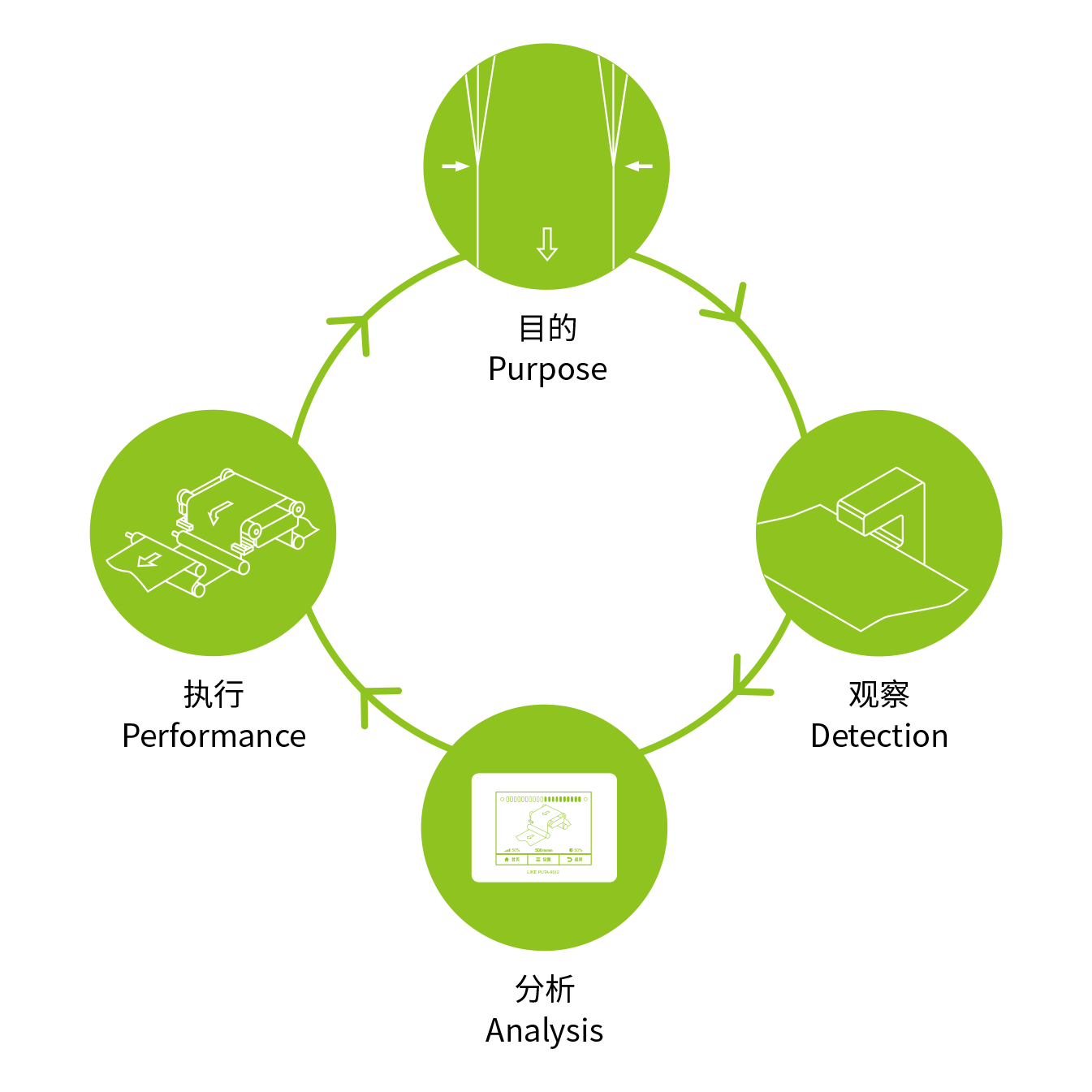

All the automation systems are based on a simple control loop, even the most complicated production procedure can be realized.

Purpose: The essential is to correct deviation of material position.

Detection: The sensor detects the material edges without touching. Sensors are available in various types of different materials, depending on the working procedure and materials adopted.

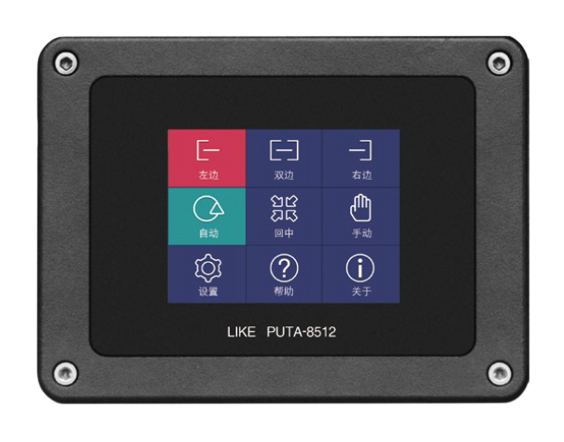

Analysis: The controller converts the actual value and preset parameter value into correction signal which is transmitted to the actuator.

Performance: The actuator corrects direction and angle of the materials to reach the purpose of web guiding.

WEB GUIDING SYSTEM

WORKING PRINCIPLE

WORKING PRINCIPLE

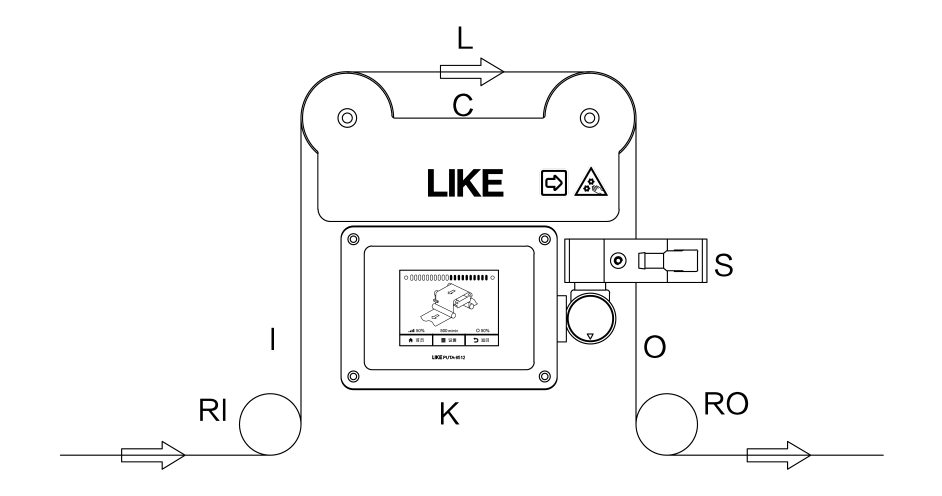

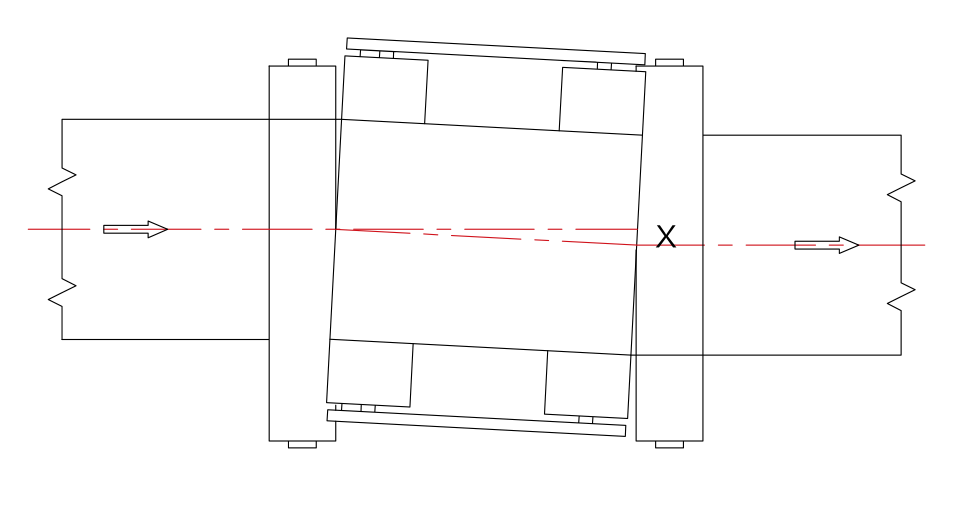

The closed-loop control system consists of the guiding controller, performing mechanism, product material and sensors. Product material are supposed to run on their own track on the produce lines; when they swaying, the sensors will produce a signal and send it to the web guiding controller. The amplified signal drives the performing mechanism's servo motor to proceed a proper guiding control, restoring the product material back to its specified position. The driving signal sent to the servo motor is a linear scale signal.

• Structure diagram