Welcome to the official website of LIKE!

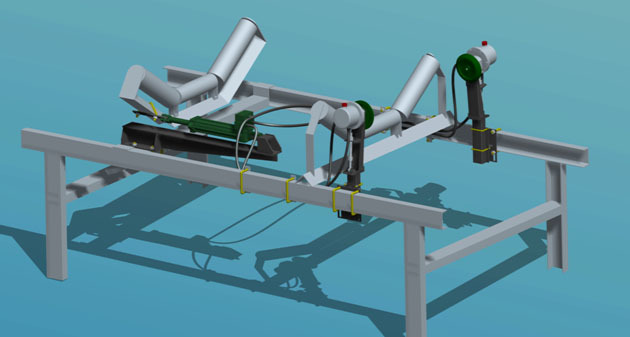

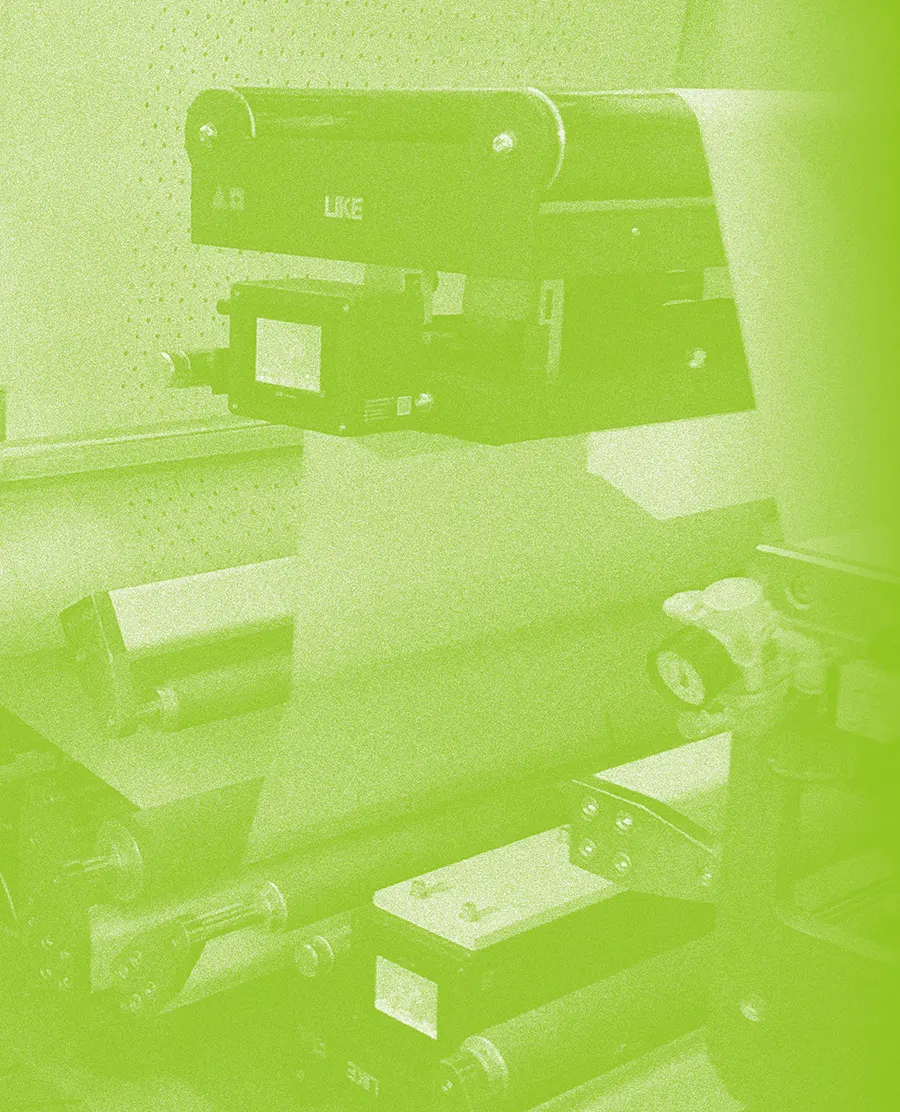

Guiding system refers to the manufacturer's coil in the spraying, printing, punching, laminating, slitting or other coil winding process, always to keep the coil side neat and consistent technical operation Its widespread use has brought great benefits to the industry, the guiding system makes printing, labels, plastic film, building materials, rubber and other industries appear automatic control. In terms of correction system, there is no lack of manufacturers in China, in order to achieve the concept of energy conservation and environmental protection, industrial correction is indispensable.

15

2022-09

Common methods and applications of building correction

Abstract: Combined with engineering examples, several commonly used building correction schemes are introduced from four aspects: soil digging and water injection correction, grouting and stacking correction, static pile correction, and steel structure correction, and the construction technology and applicable conditions of each scheme are elaborated, so as to select the appropriate correction scheme according to the characteristics of the building.

06

2023-04

Method of operating the photoelectric correction system

Due to the good photoelectric switch, the detection distance meets the requirements. According to the packaging paper you use, refer to the following light source selection guide table to determine the switching light source (take green as an example) and then decide the bright or dark motion of the output mode according to the mechanical needs of your photoelectric entanglement system. Finally, adjust the sensitivity according to the following three steps (the following according to the output lighting mode, the packaging symbol is light color, and the back shadow is dark as an example).

06

2023-04

06

2023-04

What are the main control methods of the guiding system?

Automatic correction control system is a closed-loop control system, controller, sensor, linear guide mechanism constitutes the basic part of closed-loop control, first the correction sensor detects the edge or line of the coil, reads out the actual position of the coil and the offset of the set position, and converts the offset into an electrical signal proportional to it, and then sends the electrical signal to the controller, the signal is amplified and calibrated by the controller, and output to the linear driver, the linear drive according to the size of the signal, drive the guiding mechanism, restore the coil to the set position. The drive signal of the current drive is only proportional to the amount of web mistracking, which enables control of a variety of different coils and guiding systems.

02

2023-03