Welcome to the official website of LIKE!

Linear Actuators

hiddenValue

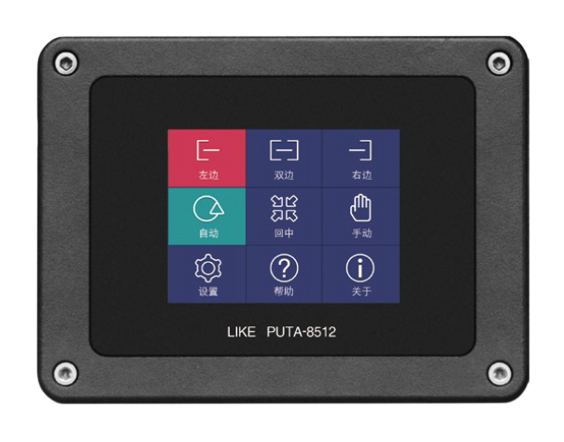

- Description

- Parameter

- After-sales service

-

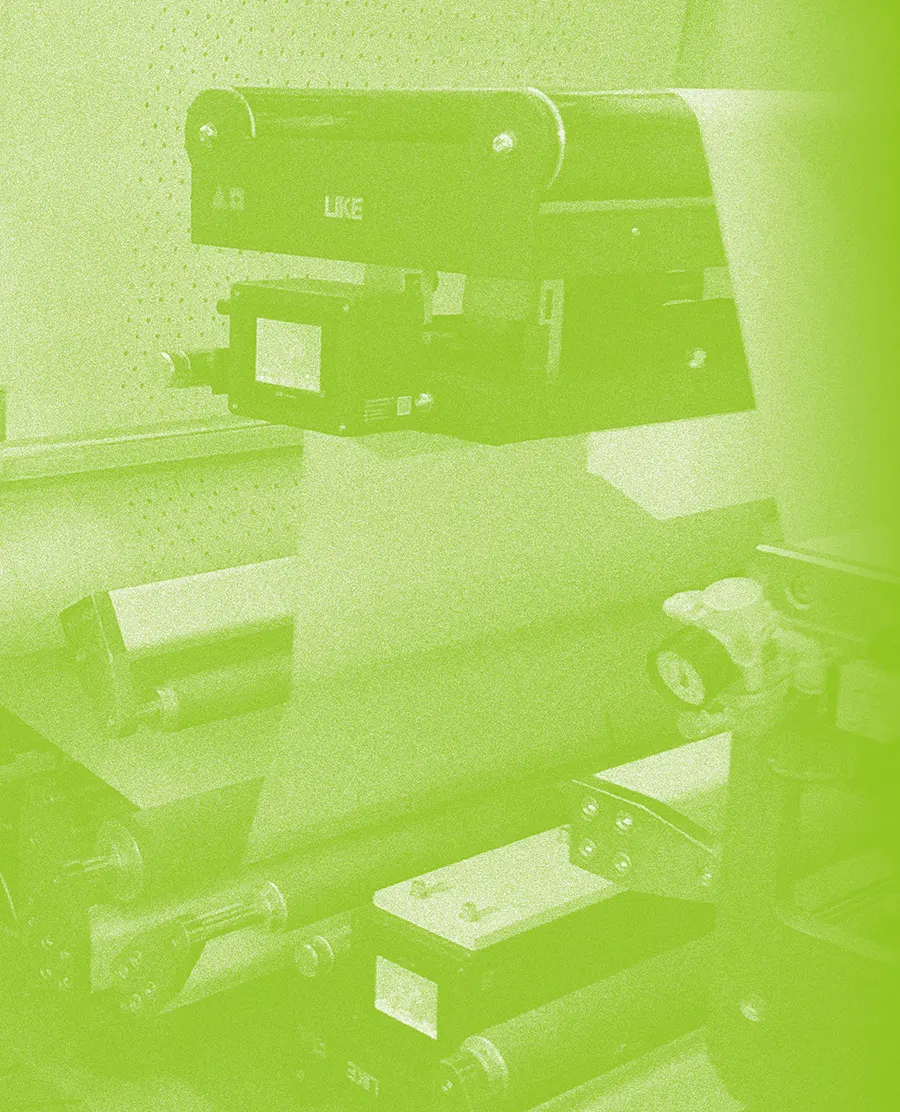

Linear actuators are mainly used in unwind and rewind mechanisms, they also apply to frame-type web guide mechanisms. The front and back installation seat is connected with the displacement web guide mechanism to realize the effect of rectifying the deviation of the material. The characteristics of linear actuators are high accuracy, high thrust, and customizable stroke, which fully meet a variety of complex station requirements, to achieve accurate web guiding.

Operation Principle Of Unwind And Winding

Most production and processing procedures involve transport of materials. The unrolling device is located at the material inlet of the machine; a linear drive keeps the feeding device running. The rolling device follows the variation of materials positions via the linear drive, so that it will be 6 positioned for taking up the materials with accurate edge alignment.

WEB GUIDING IN THE PROCESS OF UNROLLING: The application is adopted for the unrolling and feeding of rolled materials. It ensures the rolled materials are unrolled at a preset position by means of changing the carrier rll's angle vertically The edge-detecting sensor is separately fixed; is position does not vary with the carrier rol's angle during the unolling and feeding process.

WEB GUIDING IN THE PROCESS OF ROLLING: The application is intended for producing a well-aligned and neat edge for rolled-up materials. Installation of rolling web guiding differs greatly from that of unrolling web guiding in that, the sensor is integrated with the rlling shat, a guide roller has to be installed between the sensor and the rolling roller, and the guide roller should be such that the rolled material form a angle of no less than 20-30。 against level surface during rolling process. In this way, as the sensor integrated in the rlling roller keeps tracking the rolled materials' edge, the edges will be aligned and neat.

-

Ultrasonic Sensor technical data Model IGU- 30 lGU - 100 IGU- 150 lGU - 200 Stroke(mm) 30 50-100 100- 150 100- 200 Max Thruse(kg/f) 50 100 180 250 Driver Speed(mm/sec) 25 20 l5 10

Related products

Product inquiry